4 Parts That Contribute to the Final Cost of a Pyrolysis Machine

Pyrolysis machines are large, industrial machines that are used to recycle waste materials into fuel. The cost of a pyrolysis machine varies depending on the size and capacity of the machine. For example, a small machine that can process 10 tons of waste per day may cost $100,000, while a larger machine that can process 100 tons of waste per day may cost $1 million. The pyrolysis plant cost also varies depending on the quality of the machine. A high-quality machine that is made with durable materials may cost more than a lower-quality machine that is made with less durable materials. However, the quality of the machine will affect its ability to recycle waste materials into fuel, so it is important to choose a machine that will be able to provide the best results.

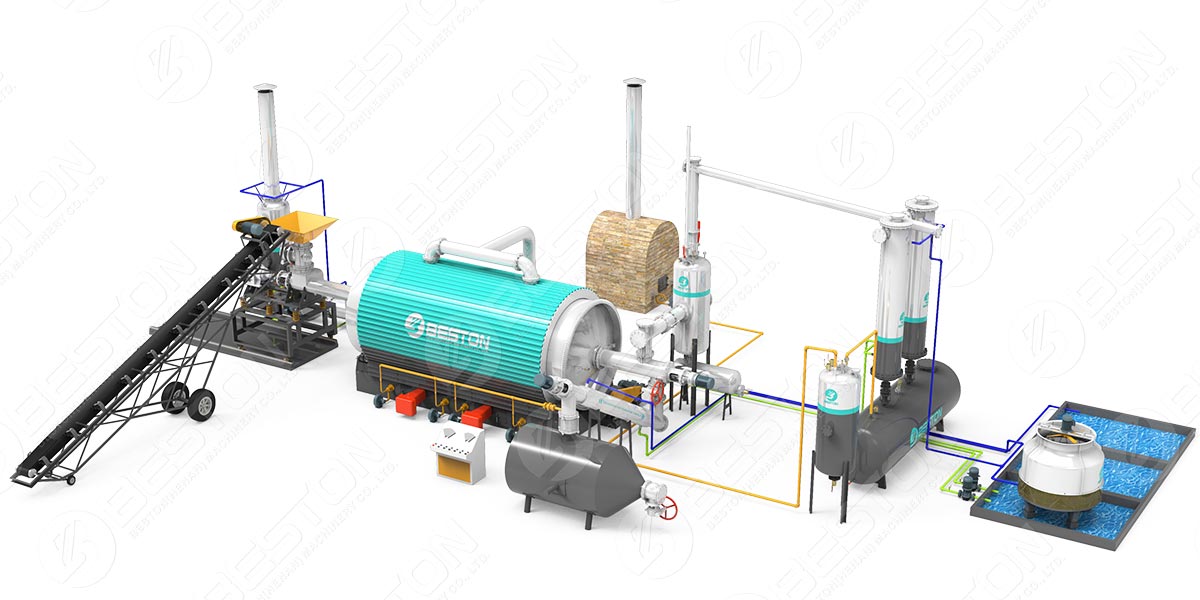

Essential Parts Of A Pyrolysis Machine

A pyrolysis machine is typically composed of four parts: feeder, reactor, condenser, and gasifier.

1. Feeder

The role of the feeder in a pyrolysis machine is to ensure a consistent and controlled flow of material into the reactor. This is important in order to maintain a stable reaction temperature and achieve the desired product yield. The feeder is typically located at the bottom of the reactor, where it can gravity-feed the material into the chamber. It sometimes comes equipped with a screw or rotary device to help move the material along. In some cases, the feeder may also be used to preheat the material before it enters the reactor, which can further improve reaction efficiency. More information on Beston Group here.

The reactor is the heart of the pyrolysis machine, where the thermal decomposition of waste takes place. It is the most expensive part of the plant. The type of reactor used will depend on the specific process and feedstock being used. For example, rotary kilns are often used for waste with high moisture content, while fluidized bed furnaces are better suited for waste with low moisture content.

3. Condenser

A condenser is the second-most expensive component in a pyrolysis machine, as it serves several important functions. The condenser cools the gasification chamber, which is necessary for the proper operation of the machine. In addition, the condenser collects and stores the products of combustion, which can be used as fuel or recycled back into the system.

4. Gasifier

Gasifiers work by heating the solid fuel to a high temperature in the absence of oxygen. This process, known as pyrolysis, breaks down the solid fuel into its component parts: gases, liquids, and solids. The gases produced by the gasifier can be combusted to produce heat or power. The role of the gasifier in a pyrolysis machine is to provide the heat necessary for the pyrolysis process. The machine’s efficiency depends on the gasifier’s ability to evenly heat the solid fuel. If the gasifier does not generate enough heat, the pyrolysis process will be incomplete and the machine will be less efficient.

If you are looking for an environmentally friendly and cost-effective way to recycle your waste, then a thermal desorption equipment may be the perfect option for you.