Beston Group Co., Ltd.: Leading the Way in Pyrolysis Technology

Beston Group Co., Ltd. is a renowned company specializing in designing, developing, and installing pyrolysis and waste-to-energy technologies. With a global presence, Beston has established itself as a leader in the field, offering advanced pyrolysis plants, waste recycling equipment, and thermal desorption units catering to various industries.

Beston’s commitment to sustainability and innovation has made it a key player in the waste-to-energy sector. The company’s range of products includes plastic pyrolysis plants, small-scale pyrolysis units, and thermal desorption systems, all of which are designed to help businesses reduce waste, generate energy, and promote environmental sustainability.

Beston’s Solutions for Plastic-to-Fuel

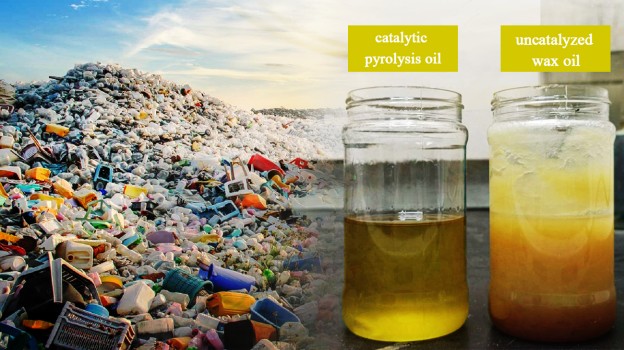

Beston’s plastic pyrolysis plants are designed to convert plastic waste into high-quality fuel oil, carbon black, and gas. These plants use advanced pyrolysis technology, ensuring maximum efficiency and minimal environmental impact. The products generated through the plastic-to-fuel process can be used for industrial heating, power generation, and as a substitute for traditional fossil fuels.

Plastic to fuel is a process where plastic waste is subjected to high heat in an oxygen-free environment, causing it to break down into hydrocarbons. The result is the production of synthetic fuel, which can be used as a substitute for traditional petroleum products. The process not only helps to reduce plastic waste but also provides an alternative energy source, helping to alleviate the growing global energy demand.

Beston’s Small-Scale Pyrolysis Units

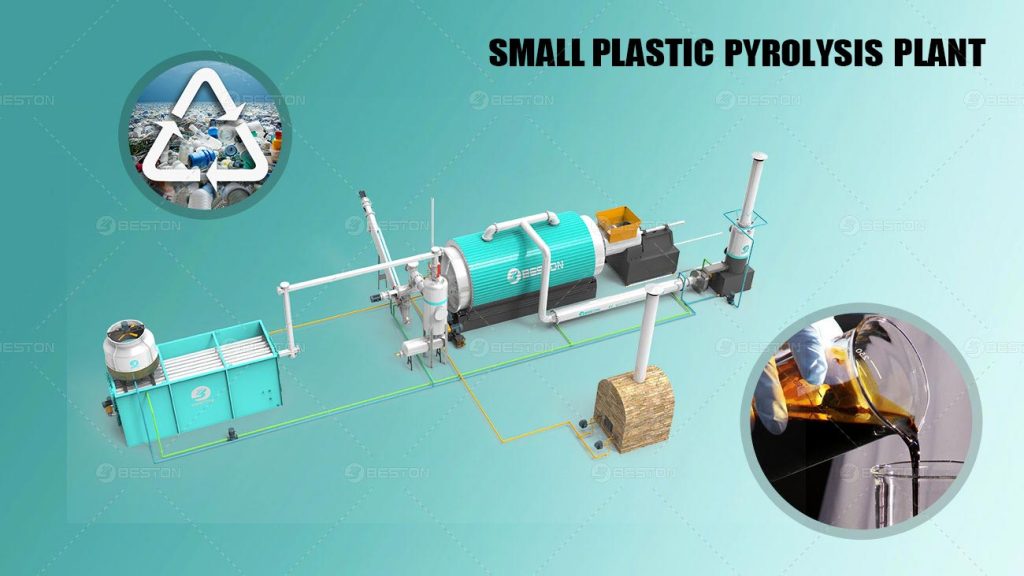

Beston Group offers a range of small scale pyrolysis unit for businesses looking for more compact and affordable pyrolysis solutions. These units are perfect for companies that want to recycle plastic, rubber, and biomass at a smaller scale, making them ideal for local waste management operations and small enterprises.

As the demand for sustainable waste management solutions grows, small-scale pyrolysis units have emerged as an excellent option for both large and small businesses looking to recycle waste materials, including plastic, rubber, and biomass. These units provide an effective means of converting various waste types into valuable products like fuel, carbon black, and gas, all while reducing environmental harm.

A small-scale pyrolysis unit operates on the same principles as a larger pyrolysis plant but is designed to cater to smaller-scale operations. They are particularly beneficial for local waste management companies, small businesses, and municipal recycling facilities that want to transform waste into energy without investing in large, expensive infrastructure.

Thermal Desorption Units by Beston

Beston’s thermal desorption units offer a safe and effective solution for treating contaminated materials, such as oil sludge, waste soils, and industrial waste. By utilizing high heat to separate contaminants from waste, these units provide a sustainable solution for hazardous waste treatment, contributing to environmental protection and energy recovery.

A thermal desorption unit (TDU) is an advanced technology used for treating contaminated soils, sludge, and hazardous waste. It works by applying heat to the waste material in the absence of oxygen, causing contaminants to vaporize and separate from the solid waste. These vaporized contaminants are then collected and treated further to meet environmental standards.

TDUs are commonly used in industries dealing with hazardous materials, such as oil spills, contaminated soils, and industrial waste. While they are often associated with large-scale waste treatment facilities, their use is also expanding in pyrolysis applications, especially when combined with smaller, more efficient units.

Why Choose Beston Group Co., Ltd.?

- Proven Track Record: Beston has been in the waste-to-energy industry for years, successfully providing pyrolysis plants and other waste recycling technologies to clients around the world.

- Innovative Technology: Beston invests heavily in research and development to stay ahead of the curve in terms of technological advancements in waste-to-energy solutions.

- Comprehensive Solutions: Beston offers a full range of services, from plant design and installation to ongoing support, ensuring that clients receive end-to-end solutions for their waste management needs.

- Sustainability Focus: Beston’s technologies are aligned with the principles of a circular economy, where waste is turned into valuable resources, reducing environmental impact and contributing to a greener future.

As the global waste crisis intensifies, the need for sustainable and effective waste management solutions has never been more urgent. Technologies like plastic-to-fuel conversion, thermal desorption units, and small-scale pyrolysis units offer innovative solutions for tackling plastic waste, hazardous materials, and other forms of waste.

Beston Group Co., Ltd. stands at the forefront of this technological revolution, providing cutting-edge waste-to-energy solutions that help businesses and municipalities reduce their environmental footprint while generating valuable resources. With a focus on sustainability, energy recovery, and environmental protection, Beston is paving the way for a cleaner, more sustainable future.