Charcoal Making Machines – Technology, Briquette Maker and Price Range

The Carbonization technology and the Ball shaped briquette maker are the most popular types of charcoal making machines. In this article, we will discuss the Carbonization technology, Ball shaped briquette maker and the price range of these machines. Hopefully, these three types of machines will be useful in determining your best buy. Let’s get started! So, which charcoal making machine will work best for you? What should you look for in a charcoal making machine?

Carbonization technology

Compared with other methods, the charcoal produced by carbonization in steel furnace is of better quality. It takes two to seven days to carbonize compared to the time needed by earth kiln. The carbonization process also uses less fuel and reduces environmental pollution. It is also convenient to use and can be installed in any location. Carbonization technology in biomass charcoal making machine is the perfect solution for large-scale production.

The process of carbonization of biomass wastes is more energy efficient, convenient, and environmental-friendly. The beston charcoal making machine can process various biomass materials with high efficiency. It can save lots of energy, has high yield, and produces charcoal with high content. It can also be used for generating electricity, since it uses high temperature pyrolysis. The carbonization process of biomass wastes is very energy-efficient, and the equipment does not emit harmful gases.

Ball shaped briquette maker

A ball-shaped charcoal making machine is a machine that forms briquettes from powdery materials with low moisture content. The pressure rollers on both sides of the carbonization machine rotate and pass materials onto them. The pressure of the rollers reaches a climactic point as the material is pressed. The material is then formed into a ball-shaped product, which can be a round, egg, heart, bread, pillow or square one. These products can be customized according to customers’ requirements.

This machine is made up of several parts, including the hopper, the gear, the press roller, the conveyor belt, the speed controller, and the motor. The ball-shaped charcoal making machine mainly produces kindle and barbecue charcoal. The end product is odorless and non-toxic. It is also environment-friendly and friendly. It is easy to operate, thanks to its high molding rate and quick-wear part-roller. The machine has a control system, as well as a photoelectric cut-off device, which can automatically stop the process when it encounters any malfunction.

Price range of charcoal making machine

The price range of a charcoal making machine depends on how much of the product it can produce. A smaller $18,000 unit can easily turn raw charcoal into several different styles. This machine is ideal for small businesses, as it can be used to produce a low volume of charcoal for a limited amount of time. Larger units, which produce a much larger volume of charcoal, are best for manufacturing plants. There is a wide variety of charcoal making machines available on the market, and choosing the one that will work best for your needs can be challenging: https://bestonasia.com/charcoal-making-machine-price/.

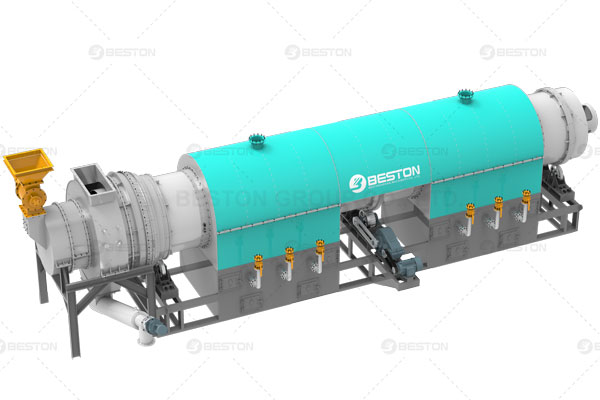

Beston is a renowned manufacturer of charcoal making machines. Their charcoal making plant is equipped with advanced designs. It comprises a carbonizing machine, drier, and auxiliary equipment. In addition to the main equipment, it also includes many supporting devices like rack, driving, and feeding. It also has a gasification furnace. The best ones from Beston Group will have a casing outside the charcoal furnace, so workers won’t have to contact it directly.