Continuous Pyrolysis Equipment: Pioneering a New Chapter in the Energy Revolution

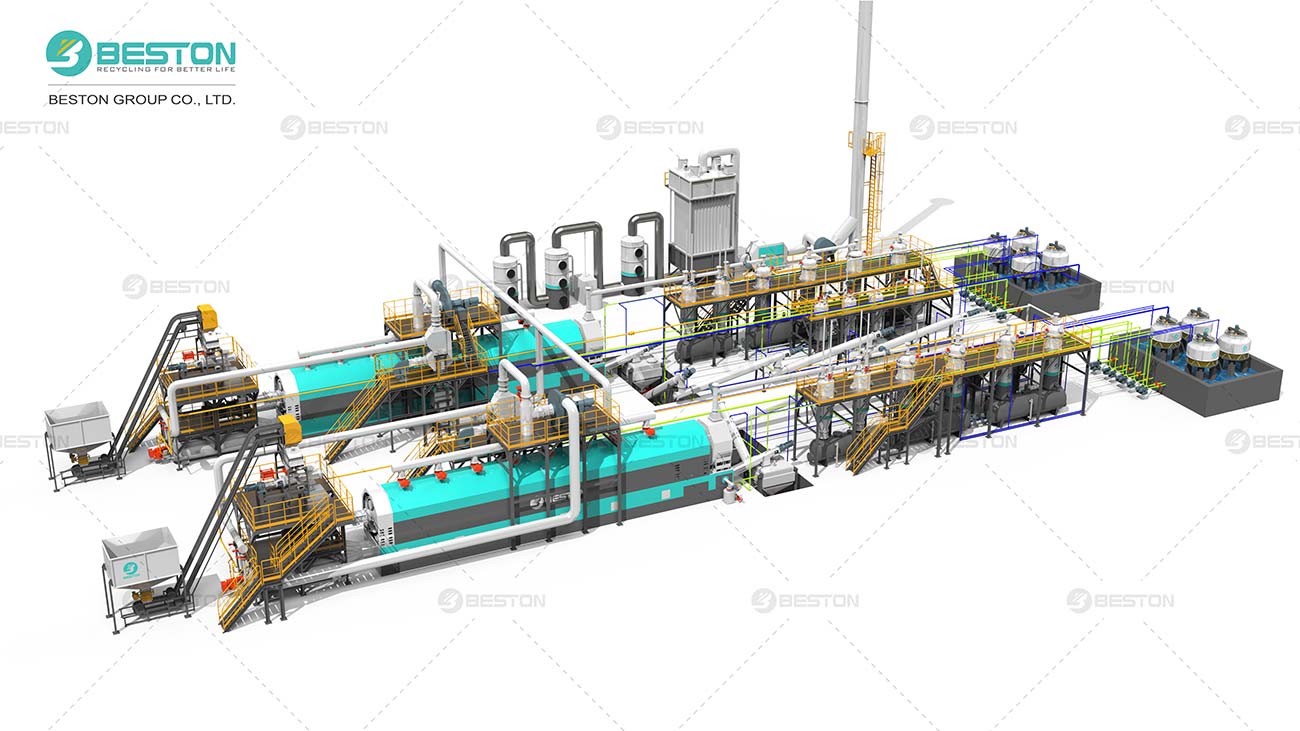

Continuous pyrolysis equipment is transforming the landscape of waste management, offering an efficient and sustainable solution for processing various waste materials. As the demand for more environmentally friendly waste processing methods grows, businesses are increasingly turning to advanced systems like the continuous tyre pyrolysis plant. Developed by industry leaders such as Beston Group, these innovations provide numerous advantages, including reduced emissions, higher throughput, and more consistent operational efficiency.

What is Continuous Pyrolysis Equipment?

Continuous pyrolysis equipment is a machine designed to convert waste materials, such as plastic, rubber, and tires, into valuable end products like fuel oil, carbon black, and syngas. Unlike traditional batch processes, which require downtime between cycles, continuous systems operate non-stop, enhancing productivity and reducing operational costs.

The continuous tyre pyrolysis plant is a prime example of this technology. It efficiently converts waste tires into reusable resources through a continuous thermal decomposition process. As waste tires move through the reactor, they are subjected to high temperatures in an oxygen-free environment, causing the breakdown of their chemical structure.

Key Features of Continuous Pyrolysis Equipment

- High Efficiency and Automation: One of the most significant benefits of continuous pyrolysis equipment is its automation level. By continuously feeding waste materials and automatically discharging end products, the system minimizes human intervention and maximizes productivity.

- Energy Recovery: Advanced pyrolysis equipment recycles the energy produced during the process. The generated syngas, for instance, can be reused to fuel the reactor, drastically reducing external energy consumption and enhancing overall efficiency.

- Environmental Benefits: The continuous tyre pyrolysis plant developed by Beston Group is designed with cutting-edge pollution control systems. These include advanced dust and odor removal technologies, ensuring compliance with environmental regulations and reducing harmful emissions.

Why Choose a Continuous Tyre Pyrolysis Plant?

For companies focused on sustainability and profitability, choosing a continuous tyre pyrolysis plant offers several advantages:

- Scalability and Flexibility: Unlike batch plants, which have limited capacity, continuous systems can be scaled up easily to handle more significant amounts of waste. This flexibility allows businesses to adapt to fluctuating waste volumes without sacrificing efficiency.

- Cost-Effectiveness: With minimal downtime and higher processing speeds, continuous pyrolysis equipment delivers cost savings through reduced labor, maintenance, and energy expenses.

- Improved Product Quality: The consistent operating conditions of a continuous plant ensure a higher quality of end products, such as cleaner fuel oil and purer carbon black.

Beston Group: Leading the Way in Pyrolysis Technology

When it comes to reliable and efficient pyrolysis equipment, Beston Group stands out as an industry leader. They have developed a range of solutions tailored to meet the diverse needs of waste management companies worldwide. Their continuous tyre pyrolysis plant is particularly noted for its robust design, innovative features, and high operational efficiency.

Beston Group’s pyrolysis systems incorporate state-of-the-art technology, such as automatic feeding and discharging systems, enhanced safety mechanisms, and real-time monitoring and control features. These elements ensure the safe and reliable operation of the equipment while maximizing output and minimizing environmental impact.

Conclusion

In conclusion, continuous pyrolysis equipment represents a breakthrough in waste management technology, offering significant benefits over traditional methods. The continuous tyre pyrolysis plant, particularly those designed by Beston Group, showcases the potential of these systems to revolutionize the way we process waste. By providing an efficient, scalable, and environmentally friendly solution, continuous pyrolysis technology is poised to play a crucial role in the global shift towards a more sustainable future.