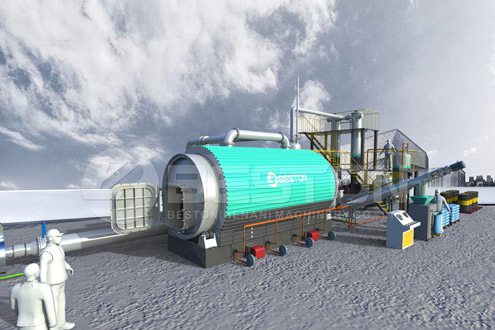

Eco Tire Recycling With A Rubber Pyrolysis Machine for Sale

A rubber pyrolysis machine for sale is used to convert rubber-based waste, particularly scrap road tires, into useful commodities. Pyrolysis, a thermal chemical reaction, is also often referred to as depolymerization, thermal cracking, thermolysis or cracking. What basically happens during the process is that rubber (or other types of waste materials) are heated to extremely high temperatures inside an oxygen-free vessel resulting in rubber polymer chains breaking apart and oils of different viscosities vaporizing. The elimination of oxygen from the reaction vessel is an essential component of facilitating vaporization as it prevents tires from catching alight, burning and outputting toxic fumes/smoke. Know more about rubber pyrolysis plant there.

To liquify the vaporized compounds, a water-cooled condensing pipe network is used. The end products from rubber road tire pyrolysis are tire oil, combustible gas, steel wire, and carbon black. In general, the combustible gas is used to stimulate a self-perpetuating process in a modern waste tyre pyrolysis machine, as it is used as fuel for the main reactor furnace.

Worldwide Tire Waste

Scrap tires are one of the globe’s most problematic waste sources. They have high durability, a large volume and are full of toxic components. Tires are essentially non-biodegradable. On a landfill site, it can take over half a century for a tire to decompose and during the decomposing period, toxins are released into the environment. Furthermore, tires use up a lot of space on landfill sites, which are already at above maximum capacity, and they present a real fire risk since methane gases can build up in the cavities.

An alternative conventional method of tire disposal, incineration, can be just as damaging to the environment as sending the waste to landfills if the incineration facility is not fitted out with high-tech emissions filtering devices. Many developing countries burn tire waste to produce energy to fuel the cement manufacturing sector. It’s not all doom and gloom for the environment, however, as tire pyrolysis recycling is becoming more and more accessible across the globe. You can find more sources to get this machine.

India’s Eco Tire Recycling Industry

Perhaps surprisingly, India is one country that is adopting rubber pyrolysis technology at an increasing rate. In Rajasthan alone, to date, there are a reported 150+ pyrolysis plants. Across the whole country, there are said to be more than 2000 rubber pyrolysis facilities. Many of the tire waste recycled in India is imported from Australia. The tires are imported in bales, so tire recycling plants in India have to buy tire shredding machines to prepare the waste for the pyrolysis reactor.

Suppliers of Waste Rubber Pyrolysis Machine for Sale

The competitive pricing of many modern tire recycling plants has made rubber pyrolysis more commercially viable and profitable than ever before. By investing in the right machinery, those in the rubber recycling industry can often make back their initial outlay within ten months. We recommend this manufacturer for you – Beston Machinery Henan.

It’s important to research prices of rubber pyrolysis machine for sale from overseas suppliers if you are looking to achieve the best ROI on a scrap tire recycling business plan. Overseas suppliers have high-quality machinery for a fraction of the cost of that sold by domestic suppliers.