Essential Equipment for Biochar Production

As global awareness of sustainable practices and carbon reduction intensifies, the production of biochar has gained increasing attention. Biochar, a form of carbon-rich charcoal, is produced through the pyrolysis of organic materials such as agricultural waste, wood chips, and biomass. This process not only reduces greenhouse gas emissions but also enhances soil fertility and water retention. To achieve efficient and scalable biochar production, various types of specialized equipment are required. This article explores the essential machinery involved in biochar manufacturing and how each contributes to a sustainable operation.

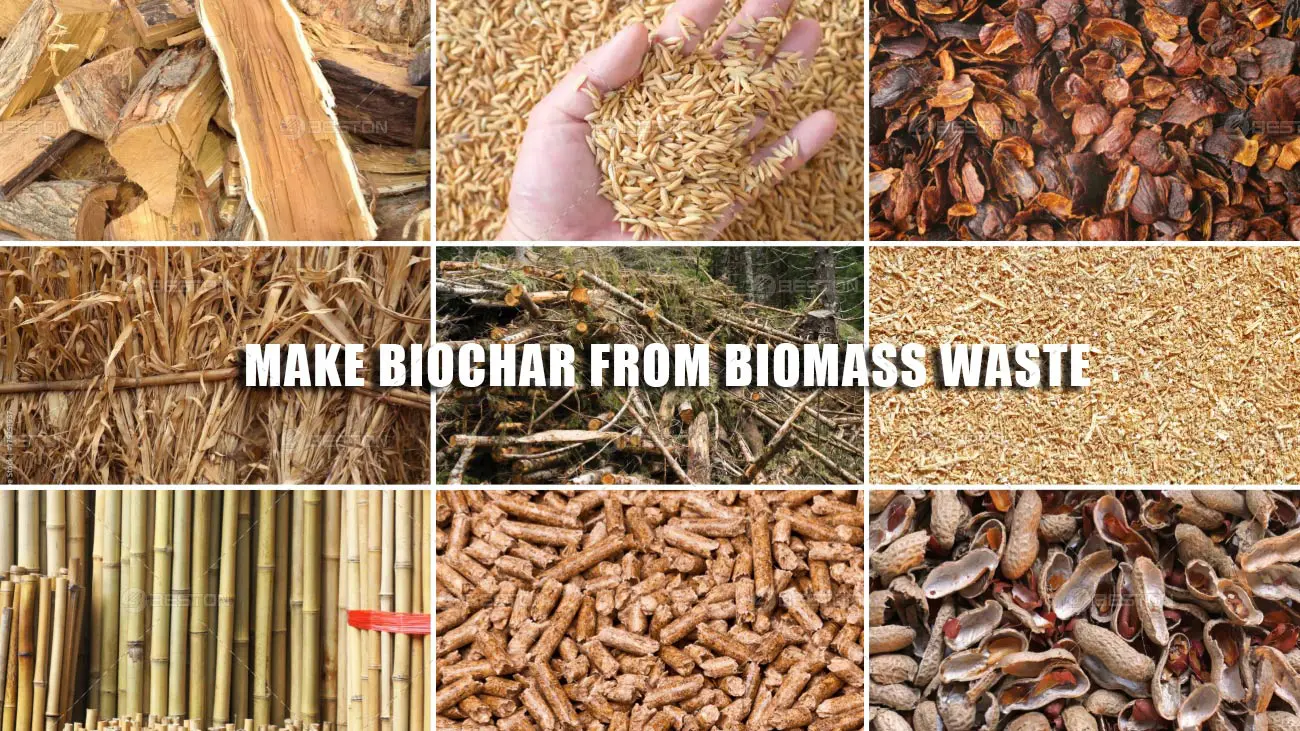

Feedstock Preparation Units

Before pyrolysis can begin, feedstock must be appropriately prepared. Preparation equipment varies based on the type of biomass. For example, if the biomass is large in size, such as logs or branches, shredders and chippers are used to reduce the material into smaller, uniform pieces. Uniformity in size ensures consistent pyrolysis and efficient energy use.

Dryers are also crucial in the preprocessing stage. High moisture content in raw materials can hinder the pyrolysis process and reduce the quality of biochar. Rotary drum dryers or flash dryers are commonly used to reduce moisture to an optimal level, typically below 15%.

Continuous Pyrolysis Reactors

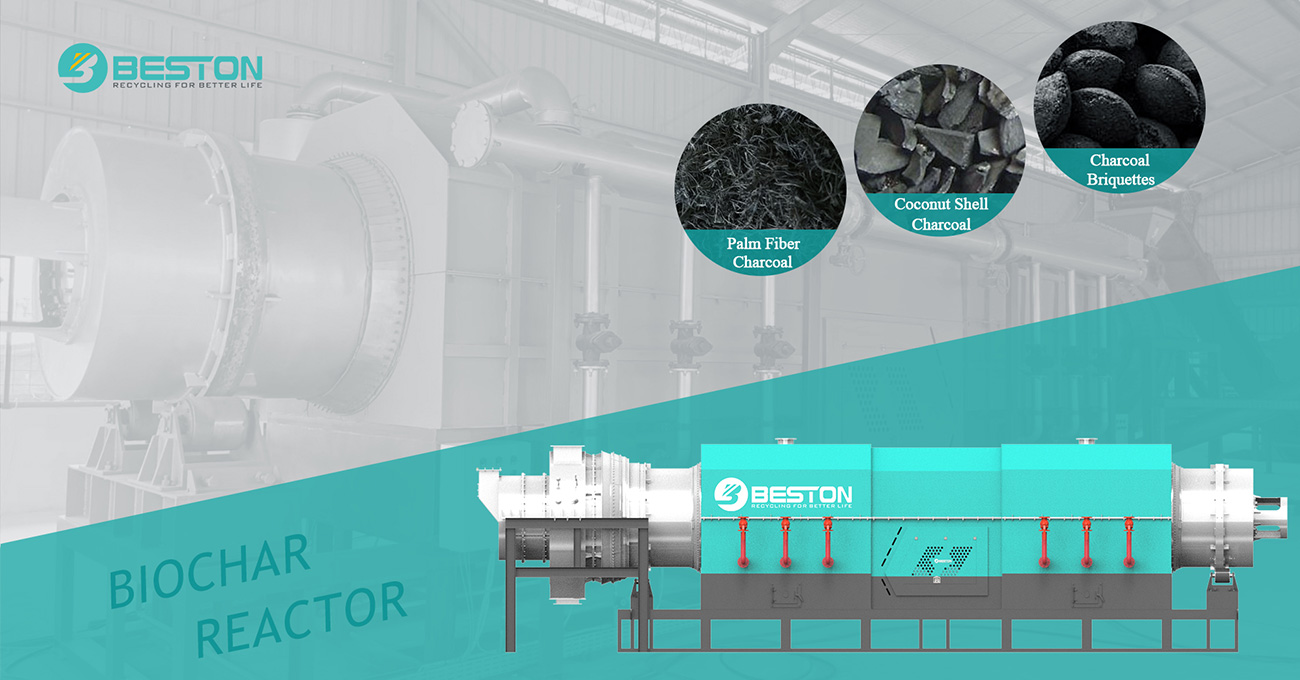

The heart of any biochar production facility is the pyrolysis reactor. This equipment thermochemically decomposes biomass at high temperatures in the absence of oxygen. There are batch-type reactors and continuous systems; the latter is more suitable for large-scale operations due to their higher efficiency and lower labor cost.

Continuous pyrolysis machines are often equipped with automated feeding and discharging systems, internal heating mechanisms, and gas recycling units. These features make the equipment energy-efficient and capable of handling various types of biomass, including sawdust, coconut shells, and agricultural waste like rice husks. For instance, a rice hull carbonizer is specifically designed to convert rice husks into high-quality biochar using advanced pyrolysis technology.

Gas Handling and Emission Control Systems

During pyrolysis, volatile gases such as carbon monoxide, methane, and hydrogen are released. Rather than being emitted into the atmosphere, these gases can be captured and reused within the system to maintain reactor temperature or generate electricity. Gas scrubbers, condensers, and filters are essential components for handling pyrolysis gases.

Scrubbers and filters remove tar, particulates, and other impurities from the gas stream. In modern facilities, emission control systems are integrated to comply with environmental standards and reduce the carbon footprint of biochar production.

Charcoal Cooling and Storage

Once the pyrolysis process is complete, the biochar must be cooled before it can be safely handled or stored. Direct exposure to oxygen while still hot can result in combustion. Water-cooled screw conveyors or cooling chambers are used to lower the temperature of biochar without exposing it to air. Once cooled, the biochar is collected in sealed bins or bags, ready for packaging or further processing.

Briquetting and Shaping Machines

Raw biochar is often irregular in shape and dusty, making it challenging to transport and apply. This is where shaping machines come into play. A charcoal briquette making machine compresses fine biochar powder into uniform, solid briquettes. These briquettes are easier to handle, store, and burn efficiently, making them ideal for commercial fuel or soil amendment applications.

Briquetting machines are available in various types, including screw press, roller press, and hydraulic systems. The choice depends on the desired output and the physical characteristics of the biochar.

Specialized Equipment for Different Biomass Types

Not all biomass is created equal. Different feedstocks require specialized machinery for optimal carbonization. For instance, palm kernel shells are a dense and high-carbon material that demands a tailored approach to pyrolysis. A palm kernel shell charcoal machine is engineered to handle this specific biomass, offering precise temperature control and efficient conversion rates. These machines are increasingly popular in regions like Southeast Asia and Africa, where palm oil production generates large volumes of shell waste.

Similarly, machines for wood chips or bamboo will have different feeding systems and heat transfer designs. Choosing the right equipment based on the biomass type is crucial for optimizing yield and ensuring long-term operational efficiency.

Automation and Monitoring Systems

Modern biochar production facilities are embracing automation to improve consistency, reduce labor, and enhance safety. Programmable Logic Controllers (PLCs), temperature sensors, and remote monitoring systems allow operators to track key parameters such as temperature, pressure, and gas composition in real-time.

Automated alarms and shutdown systems are also integrated to prevent accidents and ensure the safe operation of pyrolysis units. These technological advancements are making biochar production more accessible and viable as a commercial enterprise.

Conclusion

The production of biochar is a promising solution for sustainable agriculture, carbon sequestration, and renewable energy. However, achieving efficiency and scalability requires a comprehensive suite of specialized equipment. From preprocessing and pyrolysis to gas treatment and briquetting, each component plays a vital role in the overall production process.

Investing in high-quality, purpose-built machines such as a charcoal production machine, or charcoal briquette making machine not only boosts output but also ensures environmental compliance and operational safety. As the demand for sustainable practices grows, so too will the importance of efficient biochar production technologies.