How Pyrolysis Applies To Waste Plastic Recycling Plants

Waste recycling has very much improved over the last decade on a global level. It is more common than ever before to recycle virtually everything including metal, rubber, and plastic. If you have a source of waste plastic constantly coming to your facility, recycling this could be a very helpful way of improving your revenue levels. It is also something that can help improve the environment. When businesses consider this, they are also thinking about how much it will cost. As long as the pyrolysis plant cost estimate can be offset by profits made by recycling the plastic, this will be a good idea for any business. This is how pyrolysis works directly with plastic recycling plant machinery.

What Does The Pyrolysis Process Accomplish?

The pyrolysis process is something that was popularized years ago. It is only because of the emphasis that people have on recycling products that can be converted into reusable fuels that there has been a resurgence in their popularity. For example, when you are able to install these at a place where rubber tires are going in landfills, this can be a fantastic way to help the environment and also make a lot of extra money. Specifically, if you can install these at a waste management company, and extract all of the plastic, you can make a sizable amount of revenue from just the daily trash that you are collecting.

Does It Need To Be A Large Pyrolysis Plant?

It is not going to be necessary to get the largest one if you have a facility that is small or medium in size. For example, if you are collecting municipal solid waste for a community that is a small city, the largest model may not be necessary. However, for metropolitan areas where there are millions of people, you will likely need more than one of their largest waste recycling plants. That is a factor that you must consider as you are considering the investment into a continuous pyrolysis equipment that can make you money. For investing in a small style plant, you can refer to the small scale plastic recycling plant project report for more info.

How You Can Get A Good Deal On These

Getting a good deal on all of these is something that can be accomplished in the Orient. There are so many companies in China that produce these on a large scale. It’s not just about the size of the oily sludge treatment system, but how many they are able to produce. They come out with new models every year, and one of them is going to be perfect for the plastic you need to recycle. The size will certainly play a factor in how much you will pay, as well as the company you are getting it from. We suggest it is better not to buy the used plastic recycling equipment, which might have problems while using.

The use of pyrolysis doesn’t have to be difficult. You should have no problem at all locating a business that can help you. You will be able to quickly assess how much money it will cost to invest in one, and then how much money you can make. The size of the unit can contribute greatly to how much profitability there is. You will soon have thousands of plastic containers being recycled, converted into reusable biofuels, that can be sold to businesses and people in your immediate area.

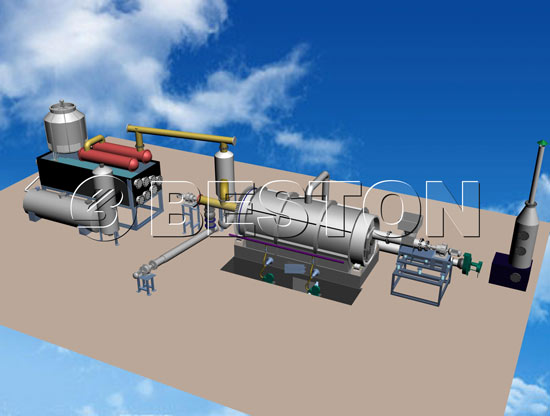

If you really are interested in this kind of technology and the machines, you are suggested to visit the website of Beston Group in China. They will provide you with the latest information of the machine.