How To Get Started With The Plastic Pyrolysis Plant

The plastic pyrolysis plant takes waste plastic and turns it into oil. This plant is powerful and it takes the waste plastic and turns it into something you can sell or use. This machine is very good for the environment and it can help you make money out of waste plastic that would end up in the landfill.

This machine is very good for the environment and it takes the waste plastic( maquina para pirolisis de plasticos ) and gets it out of the landfills. The machine is going to help get all of the plastic out of the landfills so you can make money with it when you are through processing it. The oil can even be processed with another machine and turned into gasoline.

Plastic doesn’t degrade when it is in the landfills and this is very bad for the environment. The plastic is building up fast and it hurts the environment and causes all kinds of problems. The plastic pyrolysis plant helps to solve this problem and it makes it easy to recycle plastic and get it out of the environment.

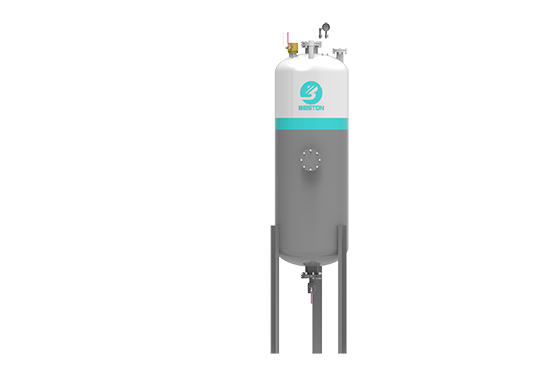

The plant melts and heats the plastic to a very high temperature where it is then turned into oil. The machine can process many different types of plastic and plastic waste. The system is semi-continuous and you can also buy a continuous plant.

The continuous plant is more expensive but it can do more since it doesn’t need as many people to run the machine. The machine is very sturdy. The plant can process plastic, tires, rubber, and oil sludge.

The machine runs on LPG, natural gas, fuel oil, wood or charcoal which makes it a very versatile machine since you can run it so many different ways. The machine is economical to run and it doesn’t produce a lot of pollution which makes the machine very good for the environment.

The pyrolysis plant ( planta de pirolisis ) is water cooled and it will run for up to 8 years before it needs to be replaced. The machine has a lot of different safety devices that ensure that is totally safe. It has an advanced dedusting system that ensures that no dust gets out into the air.

The machine doesn’t produce a lot of gas and it doesn’t use a lot of energy which makes it very economical to run. You don’t have to spend a lot of money running the mahine and this helps you save money. When the machine is in operation 95 percent of the dust is going to be removed. The gas that the machine produces is pollution-free and it can be removed directly into the air.

The machine can draw a lot of oil out of the plastic. It has a tubular condenser ( condensador tubular ) that has a large cooling area which makes the machine faster to cool. You get a lot of oil from the machine and it the special condenser makes the process much faster. It is important to pretreat the plastic. It will need to be dried and crushed so the machine is as efficient as possible.

Find the best recycling machine: www.bestoneco.com/