The Advantages Of The Sawdust Charcoal Making Machine

The products that are produced from the sawdust charcoal making machine typically include tar, wood vinegar, combustible gas, and sawdust charcoal. All these products are regarded as useful resources that are used in several commercial and industrial applications.

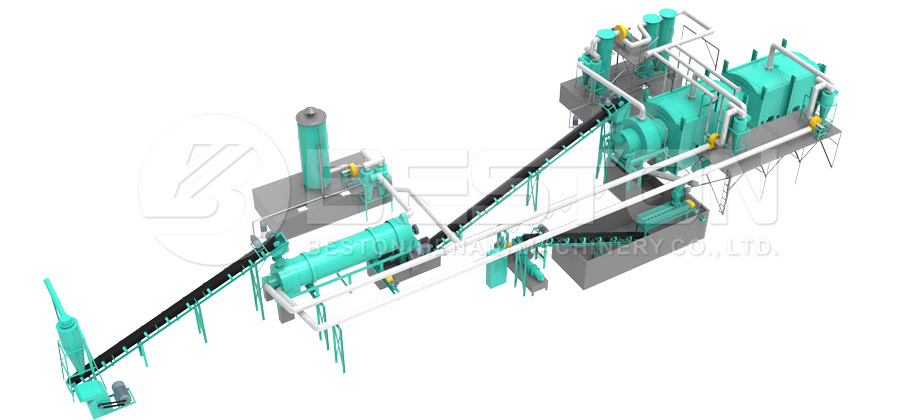

Today, the process of turning sawdust into charcoal has become an extremely popular trend which is able to produce favorable profits. With its long service life, minimal maintenance, outstanding corrosion resistance, high flexibility, and durable construction, the sawdust charcoal making machine is the ideal choice for these important applications.

Introduction To The Process Of Making Charcoal From Sawdust

The process involved to turn sawdust into charcoal follows 4 steps. This includes high-temperature pyrolysis, discharge of smoke, sulfur emission, and finally enrichment of charcoal. The first step of the process involves heating the sawdust in a furnace which generates the charcoal and combustible gas. These are both end products that are used for different purposes.

Once the combustible gas is purified through the spray-dedusting system, the gas is then recycled and used again to supply heat to the dryer and furnace rather than the coal. This contributes to lowering the consumption of costs and energy. Click here to know more: https://bestonpyrolysisplant.com/.

The Applications Of Charcoal Produced From Sawdust

The charcoal that is produced from sawdust offers a range of applications in many industrial, commercial, and agricultural applications. For industrial applications, the charcoal is used in the form of an additive for producing activated carbon, it is also combined with clay in the brick making process. This charcoal is also useful in homes as a fuel for heating and cooking purposes. In agricultural applications, this charcoal made from sawdust with charcoal production plant is used to promote soil aggregation, improve the soil and regulate the microbes present in the soil. It is also a great additive to reduce the content of heavy metals present in the soil.

Environmentally Friendly Sawdust Charcoal Machine

The equipment present in the Sawdust Charcoal Making Machine is designed in such a way that it does not generate residue waste, due to the absence of chemicals and additives in the process of production.

The high-quality charcoal produced from sawdust also does not produce any waste liquids as the process does not require water. The products that are generated from the sawdust in these processes also do not generate any waste gas. The production process produces steam along with combustible gas which is in turn is recycled to heat the dryer and the furnace. This system ensures that air pollution is kept to a minimum. More relevant information on http://www.ummria.portfoliobox.net/.